You are a professional in the electrical energy sector

Eurofins IESPM is the preferred partner of maintenance departments, and has been helping professionals monitor all types of equipment with its lubricant and fluid analysis techniques for over 60 years.

The challenges of monitoring your transformers

Transformers are a key element of the power grid for all those involved in the production and distribution of electricity. Like all high-voltage equipment, transformers present a risk of explosion and fire. This type of accident has far-reaching consequences, including the destruction of infrastructure, environmental pollution and the death of technicians and local residents. What’s more, in the case of an industrial unit, if the transformer is not replaced, damage can lead to partial or total loss of production, from a few hours to several months, depending on the transformer affected.

ECONOMIC AND TECHNICAL ADVANTAGES OF DIELECTRIC FLUID ANALYSIS

Economic benefits

- Low investment investment : The average cost of a follow-up analysis is between 200 and 300 euros. Depending on the age of the processor and its analysis history, 1 to 2 analyses per year are recommended.

- Reduced transformer purchase and maintenance costs over the long term

- Significant purchases of parts and lubricants

- Optimization equipment lifespan: some of the transformers we monitor are over 70 years old. proper care, optimized maintenance, guaranteed longevity!

- Improved ROI: Transformers are indirectly involved in all industrial production operations, since they are the source of energy for the machine park. A transformer out of service brings the entire production process to a standstill, resulting in heavy operating losses.

Technical advantages

- Optimization condition-based maintenance

- Monitoring easier and less costly (simple sampling without machine downtime or dismantling)

- Monitoringcondition of fluids, wear and tear of equipment and other damage (manufacturing defects, voltage peaks, heat and humidity overload, short-circuits, oil degradation)

- Help to manage interviews

- Guarantee safety of teams, infrastructure and local residents, and reduced environmental pollution through preventive maintenance

Environmental benefits

- Improvement and adjustment engine combustion efficiency

- Reduce lubricant consumption

- Control the quality of the working environment and prevention of employee health risks

PCB regulatory framework and recommendations

Polychlorinated biphenyls (PCBs) are persistent organic pollutants, i.e. substances that break down very slowly in the environment and accumulate in various media, particularly soil. Manufactured since the 1920s, they were massively used as lubricants (turbines, pumps) and in the manufacture of electrical transformers and capacitors between the 1930s and 1970s. (Leon Berard Cancer Center).

The government’s 2002-2010 national elimination and decontamination plan requires holders of electrical appliances polluted with more than 50 ppm of PCBs to decontaminate or dispose of them through authorized or approved companies, according to the following schedule:

– Before January 1, 2017: If manufactured before January 1, 1976.

– Before January 1, 2020: If manufactured after January 1, 1976 and before January 1, 1981.

– Before January 1, 2023: If manufactured after January 1, 1981.

The IESPM analysis report will then guide you in the actions you need to take.

See our special training course on transformer monitoring using dielectric fluid analysis :

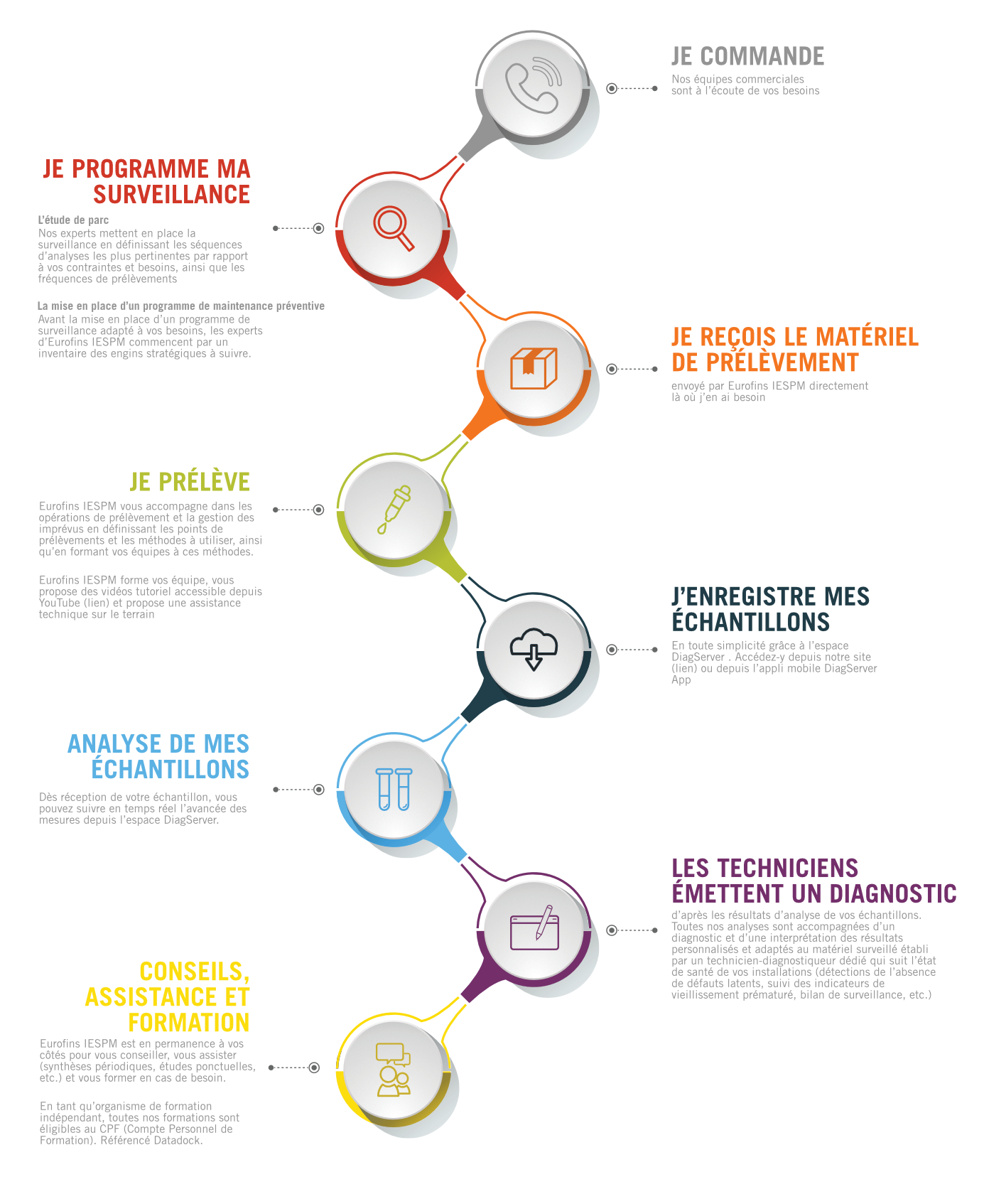

IESPM and you: stages in a win-win partnership

In an economy that is increasingly focused on the user experience, and in which the digitalization of services has become essential, IESPM is reinventing its customer relations by striving to establish a genuine relationship of trust and long-term partnership with all its customers, both professionals and private individuals.

“By being attentive to our environment and listening to our customers, we can innovate and constantly improve our processes to meet their expectations. 1+1=3 is our way of expressing that together we form a winning partnership to bring our customers more service, performance and peace of mind in the management of their risks.”

How is the partnership between Eurofins IESPM and its customers organized?

NEWS

Delta tangent measurement

Delta tangent: a precise measurement for monitoring the insulating and heat transfer functions of dielectric fluids…

SPECIAL REPORT

Dielectric fluid analysis

Find out in our special report how regular monitoring of dielectric fluids is the simplest and least expensive way of optimizing the maintenance of your electrical equipment…