You are a professional in the energy sector

Eurofins IESPM is the preferred partner of maintenance departments, and has been helping professionals monitor all types of equipment with its lubricant and fluid analysis techniques for over 60 years.

As professionals in the energy sector, your priority is to ensure and maintain your power plants. Your machines are at the heart of your business, and represent a heavy financial investment.

Our experts can help you define and implement afluid analysis system to optimize your production, avoid malfunctions and plan the replacement of faulty and/or ageing equipment.

Eurofins IESPM supports the major players in the electrical sector in the maintenance of their installations, from power generation (generator sets, cogeneration, turbines, wind turbines) to distribution.

Production: focus on the wind power sector

Whether you’re a wind turbine manufacturer, a wind farm operator, a maintenance specialist or an auditor, you need to pay special attention to the strategic components of wind turbines to ensure their smooth operation, productivity and longevity.

The expected lifetime of a wind turbine is estimated at over 20 years, so proper maintenance is essential to ensure good energy production throughout this period.

Analyzing the fluids present in wind farms (oil, grease, dielectric fluid, etc.) enables you to anticipate breakdowns, plan interventions on a case-by-case basis, control your maintenance costs, increase the availability of wind turbines and therefore their productivity.

We support you throughout the lifecycle of your wind turbines, from manufacture to maintenance, using fluid analysis techniques.

Manufacturing

You need to choose the right lubricant for the different types of wind turbine components (gearbox, pitch system, hydraulic circuit, nacelle rotation, generator, rotor, etc.).

Our R&D laboratory, Eurofins BfB Oil Research (link), can help you select the most suitable lubricant, for example by carrying out specific performance tests.

Wind farm acquisition

From the moment you acquire your wind turbines, we will support you in setting up monitoring: definition of the strategic organs to be monitored, setting up a sampling protocol, planning samples, ZERO point (initial property assessments), etc.

During and especially after the warranty period of your wind turbines

- Setting up monitoring (defining analysis sequences and sampling frequencies)

- Managing the unexpected

- Monitoring the health of wind turbine components

- Surveillance report

- Feedback.

For transport and distribution

Dielectric fluids are present in all electrical installations and networks:

- Electricity production networks: power transformers, which raise or lower voltage, and voltage transformers require specific monitoring.

- Electricity transmission networks

- Electricity distribution networks: Eurofin IESPM monitors transformers and circuit breakers in particular

We support you throughout the lifecycle of your electrical installations, from commissioning to end-of-life, with fluid analyses. Our expertise enables us to advise you on the best monitoring program for your business. When an anomaly is detected, we propose additional checks to recommend an appropriate solution (oil change, equipment change, etc.).

To find out more about our transformers, please visit our dedicated page.

The challenges of monitoring your wind turbines and wind farms

Analyzing the lubricants used in the key components of wind turbines enables us to check their quality, give an overall indication of the condition of the equipment without dismantling it, detect damage and emerging anomalies (insoluble pollution, abnormal wear, presence of water, overheating, etc.) and identify the causes of failure in order to choose between corrective action, repair or replacement.

This maximizes fluid service time, optimizes the fluid budget, and provides greater peace of mind for teams, thanks to better detection and prevention of damage.

ECONOMIC AND TECHNICAL BENEFITS OF FLUID AND LUBRICANT ANALYSIS

Economic benefits

- Low investment investment

- Reduced long-term maintenance costs

- Significant purchases of parts and lubricants

- Optimization equipment lifetimeI

- Improve ROI

Technical advantages

- Optimization condition-based maintenance

- Monitoring easier and less costly (simple sampling without machine downtime or dismantling)

- Monitoringfluid condition, equipment wear and other anomalies (degradation, oil oxidation, water contamination, etc.)

- Help to manage interviews

Environmental benefits

- Improvement and adjustment engine combustion efficiency

- Reduce lubricant consumption

- Control the quality of the working environment and prevention of employee health risks

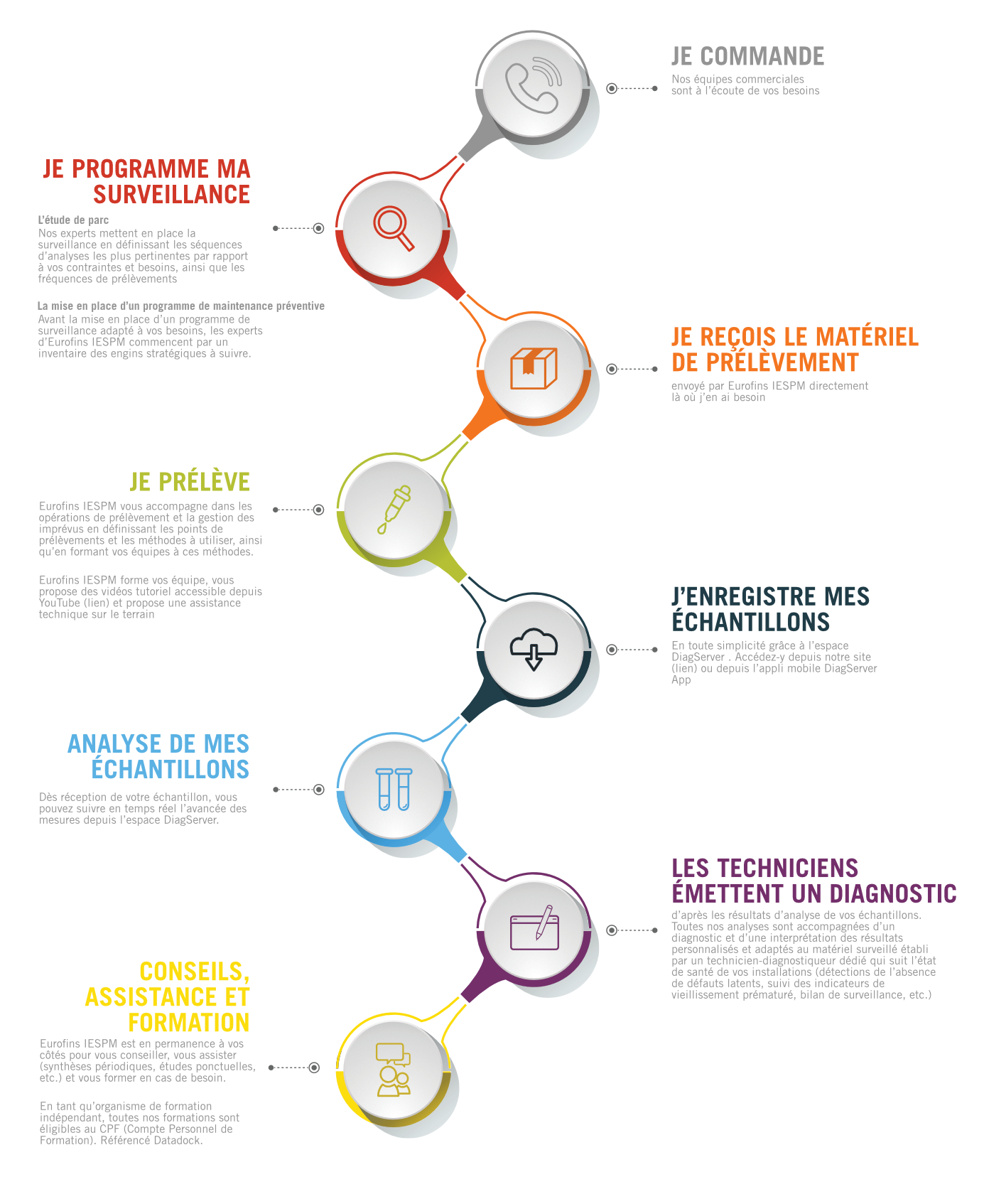

IESPM and you: stages in a win-win partnership

In an economy that is increasingly focused on the user experience, and in which the digitalization of services has become essential, IESPM is reinventing its customer relations by striving to establish a genuine relationship of trust and long-term partnership with all its customers, both professionals and private individuals.

“By being attentive to our environment and listening to our customers, we can innovate and constantly improve our processes to meet their expectations. 1+1=3 is our way of expressing that together we form a winning partnership to bring our customers more service, performance and peace of mind in the management of their risks.”

How is the partnership between Eurofins IESPM and its customers organized?