You are a metalworking professional

Eurofins IESPM is the preferred partner of maintenance departments, and has been helping professionals monitor all types of equipment with its lubricant and fluid analysis techniques for over 60 years.

The stakes of monitoring your industrial equipment

As a manufacturer, subcontractor (automotive, aeronautics, …), metal parts plant manager or general engineering company, you use soluble cutting oils for your metalworking operations such as machining (turning, milling, boring, drilling, tapping, broaching, bar turning, …), grinding, deforming, …

Implementing equipment monitoring using machining fluid analysis techniques gives you control over..:

Machining quality (conformity rate)

Production costs (tool consumption, etc.), machining fluid operating costs and maintenance costs (prevention of unplanned stoppages).

The quality of your working environment

ECONOMIC AND TECHNICAL BENEFITS OF FLUID AND LUBRICANT ANALYSIS

Economic benefits

- Reduction of maintenance costs

- Extension of the service life of lubricants and equipment

- Reduce purchases of parts and lubricants

- Impact positive impact on ROI: reduction in operating losses due to breakdowns

Technical advantages

- Peace of mind for teams: fewer unexpected stops, intervention planning, and identification of breakdown causes to guide maintenance operations

- Non-intrusive monitoring without disassembly or machine shutdown, thanks to a simple sampling

- 2 in 1: monitoring fluid condition (property, pollution) and equipment wear

- Help to manage interviews

Environmental benefits

- Reduce lubricant consumption

- Extending of production equipment

- Reducing health risks related to the possible presence of toxic compounds in lubricants

The benefits of cutting fluid analysis by our expert:

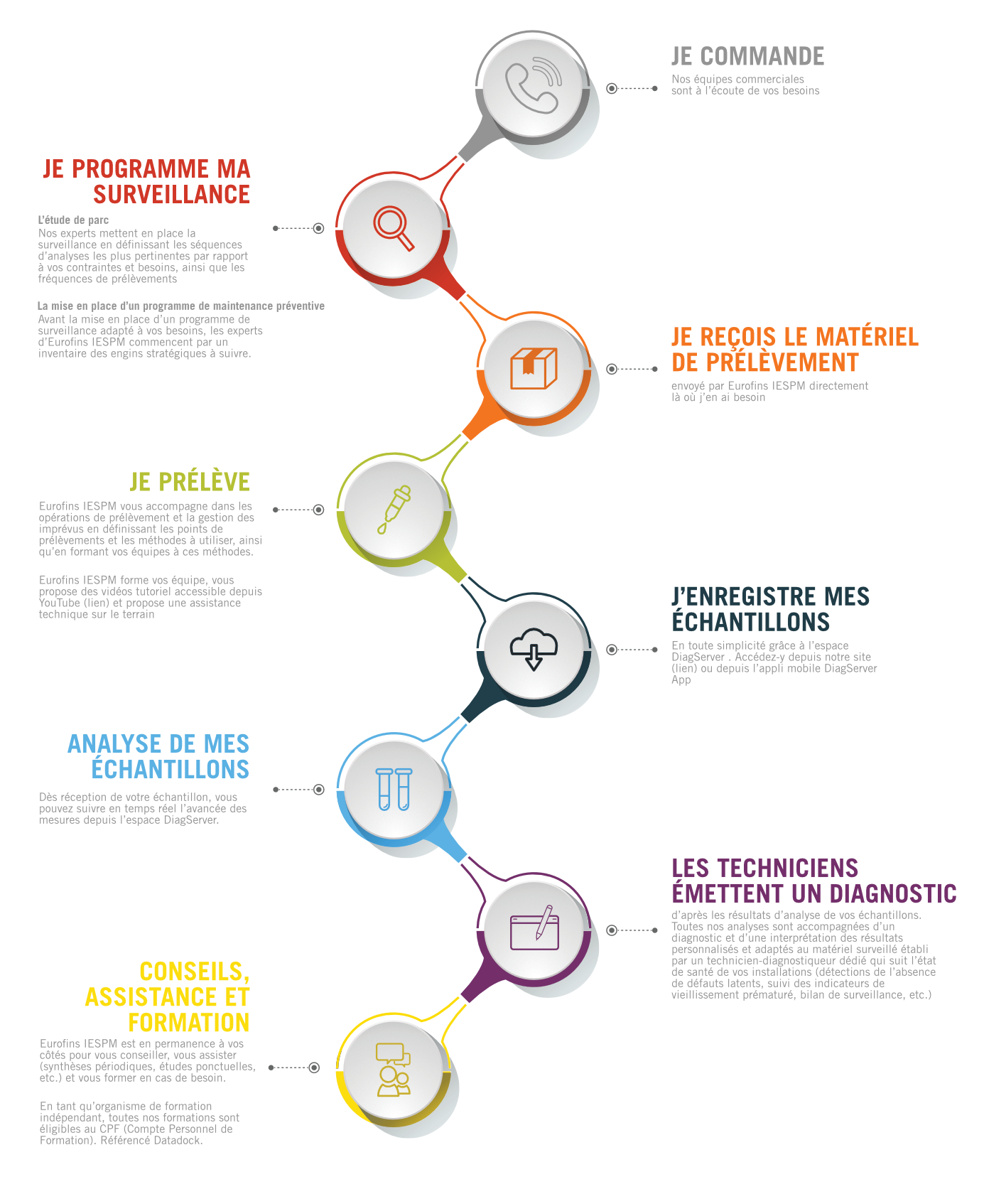

IESPM and you: stages in a win-win partnership

In an economy that is increasingly focused on the user experience, and in which the digitalization of services has become essential, IESPM is reinventing its customer relations by striving to establish a genuine relationship of trust and long-term partnership with all its customers, both professionals and private individuals.

“By being attentive to our environment and listening to our customers, we can innovate and constantly improve our processes to meet their expectations. 1+1=3 is our way of expressing that together we form a winning partnership to bring our customers more service, performance and peace of mind in the management of their risks.”

How is the partnership between Eurofins IESPM and its customers organized?

SPECIAL REPORT

Soluble fluids

Discover all the benefits of regular analytical monitoring of soluble fluids in your equipment in our special report.

VIDEO

The benefits of analysis

cutting fluids

Find out more about the importance of monitoring these lubricants in interviews with our cutting fluids expert.